Types of Plating Procedures

Plating has been done for hundreds of years. This includes the procedure of placing a surface covering in which a metal is transferred on a conductive surface area.

With modern innovation plating procedures has achieved premium quality standards that make certain efficient processes you can take advantage of.

Other than utilizing it for attractive functions, plating treatments are likewise ideal for rust inhibition, for boosted solderability, wearability, and also strength, for rubbing decrease, for improved paint adhesion, for radiation protecting and many others.

You can additionally pick from a number of layering techniques to suit your style. Plating methods consist of vapour deposition under vacuum and also sputter deposition or might be done making use of liquid compounds.

Due to the fact that we understand your needs we offer you just the most effective plating solutions that can absolutely please your taste.

The adhering to are among the top quality plating treatments you can select from:

Electroplating

This refers to the process in which an ionic steel is supplied with electrons to form a non-ionic covering on a substratum or a base product.

It frequently includes an anode which is a chemical remedy that takes the ionic form of the metal and also a cathode where electrons are supplied to create a film of non-ionic metal.

You can achieve a range of end results for your material depending on the layers or mixes of finishes of your choice.

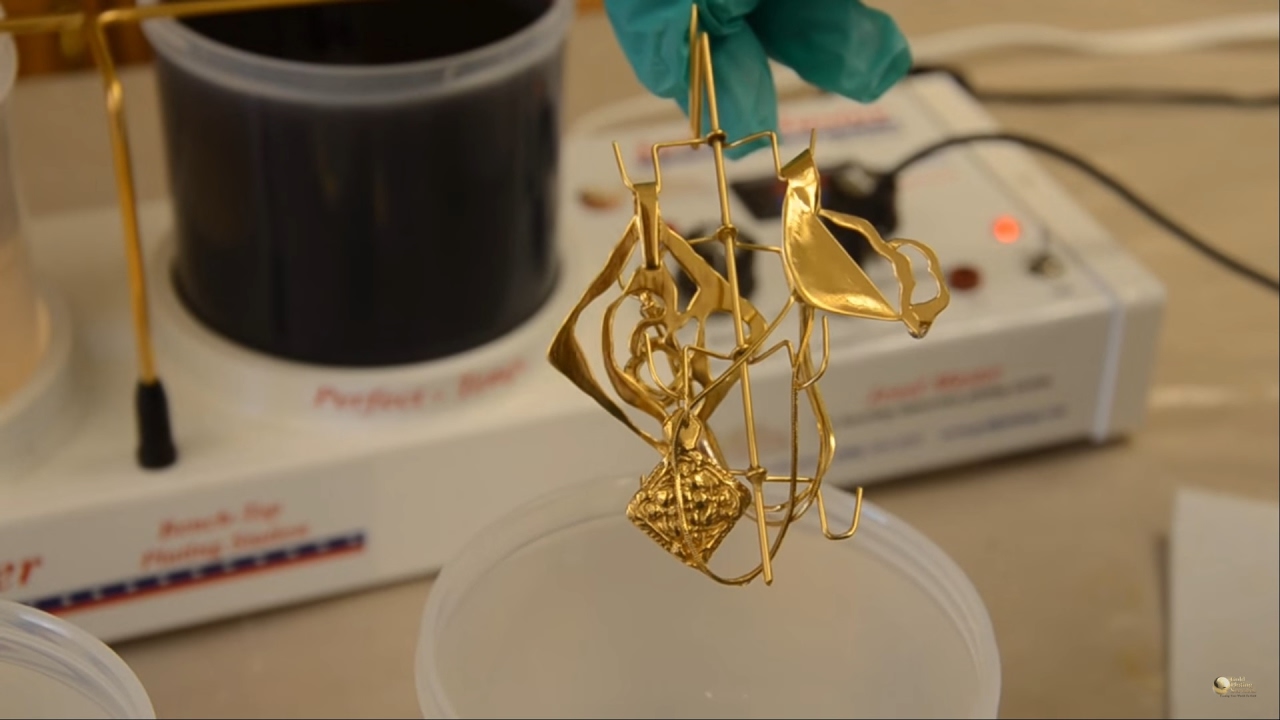

Gold plating

This refers to the technique of transferring a thin layer of gold externally of glass or steel however most generally done on copper or silver.

Whether used for electronic devices or decorative functions, gold plating is a superb choice because of its anti-tarnish homes and good conductivity. It makes certain tougher using as well as much longer long-term items that you can take pleasure in with style as well as timeless sophistication.

Silver Plating

This procedure is a less expensive replacement of gold. It is an electrolytic process that is typically applied over initial coatings of copper or gold plating services nickel. Silver plating is recognized for its functional and also decorative purposes.

Bonus care need to be used for parts revealed to high moisture settings as it can create flaking off the plating and also revealing the substratum.

Amanda Timber is Taking Care Of Director of South Australian Metal Ending up firm A Course Metal Finishers Pty Ltd. A Course is a leading carrier of electroplating, metal sprucing up and also various other steel surface treatment solutions.